The global copper alloys for connector market was valued at USD 3.02 billion in 2024 and is projected to reach USD 5.54 billion by 2033, growing at a CAGR of 7.4% from 2025 to 2033. Market growth is driven by the rapid expansion of the electronics and electrical industries, particularly in Asia Pacific and North America.

The proliferation of smartphones, tablets, wearable devices, and smart appliances has significantly increased demand for compact, high-performance connectors. Copper alloys are preferred in these applications due to their excellent electrical conductivity, thermal stability, and mechanical resilience. As consumer electronics evolve toward smaller and more powerful designs, the need for efficient, durable connectors made from advanced copper alloys will continue to rise.

The electric vehicle (EV) sector also fuels demand, requiring highly reliable connectors for battery systems, charging infrastructure, and powertrain components. Alloys such as beryllium copper and copper-nickel-silicon provide the durability and performance required in these high-stress applications. With government incentives and regulations accelerating EV adoption, the demand for connector-grade copper alloys in automotive applications is expected to grow rapidly.

Key Market Trends & Insights

- Region: Asia Pacific dominated the market with a 66.0% revenue share in 2024.

- U.S. Market: Expected to grow at a CAGR of 6.8% from 2025 to 2033.

- Alloy Type: High-conductivity copper alloys accounted for the largest revenue share of 38.7% in 2024.

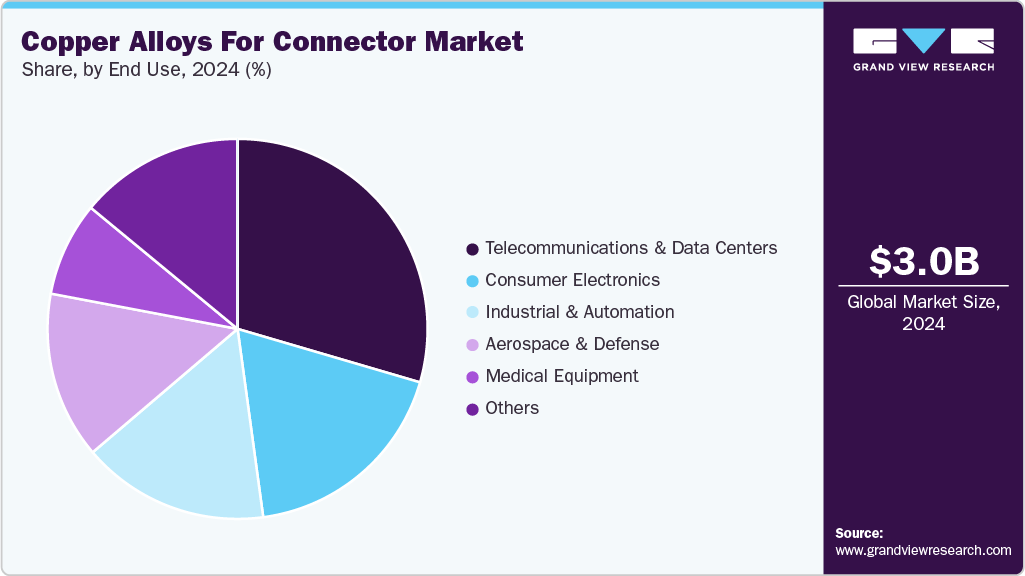

- End Use: Telecommunications & data centers held a 29.5% revenue share in 2024.

Download a free sample PDF of the Copper Alloys for Connector Market Intelligence Study by Grand View Research.

Market Size & Forecast

- 2024 Market Size: USD 3.02 Billion

- 2033 Projected Market Size: USD 5.54 Billion

- CAGR (2025–2033): 7.4%

- Largest Market (2024): Asia Pacific

Competitive Landscape

The market is highly competitive, with key players focusing on innovation, metallurgical expertise, and customized alloy solutions to meet the evolving needs of electronics, automotive, and industrial applications.

- AMPCO METAL: A global engineering materials provider specializing in advanced alloy solutions for aerospace, automotive, defense, marine, oil & gas, and electronics. Known for research-driven development of alloys with high conductivity, corrosion resistance, and mechanical strength.

- KME Group: One of the world’s largest producers of copper and copper-alloy products, delivering rolled products, tubes, bars, cables, and custom-engineered components for electronics, automotive, architecture, and energy sectors.

Prominent Companies

- AMPCO METAL

- KME Group

- Lebronze Alloys

- Materion Corporation

- Mitsubishi Materials Corporation

- Nexans

- NGK INSULATORS, LTD.

- Proterial, Ltd.

- thyssenkrupp Materials Services GmbH

- Wieland Group

Explore Horizon Databook – the world’s most comprehensive market intelligence platform by Grand View Research.

Conclusion

The global copper alloys for connector market is poised for substantial growth, driven by increasing demand from consumer electronics, telecommunications, and the electric vehicle industry. Superior properties of copper alloys, such as high conductivity, durability, and thermal stability, are making them indispensable in miniaturized and high-performance connector applications. With Asia Pacific leading the market and ongoing technological advancements in alloys, the sector is expected to witness sustained expansion, offering significant opportunities for manufacturers to innovate and cater to the evolving needs of electronics and automotive industries.

No comments:

Post a Comment