The global vacuum grease market was valued at USD 139.1 million in 2023 and is projected to reach USD 209.2 million by 2030, expanding at a CAGR of 6.0% from 2024 to 2030. Market growth is primarily driven by the rising demand for high-performance sealing lubricants across industries such as food processing, pharmaceuticals, aerospace, and advanced manufacturing, along with the increasing adoption of heavy and precision machinery.

Vacuum grease is extensively used in environments that require contamination-free operation. A growing number of industrial and research processes are conducted under vacuum conditions to minimize exposure to contaminants, making vacuum-compatible lubricants essential. As a result, the widespread use of vacuum chambers, sealed systems, and controlled manufacturing environments is positively contributing to market growth over the forecast period.

Vacuum grease also plays a critical role in maintaining cleanroom environments, particularly in the pharmaceutical and biotechnology sectors, where sealing and lubrication are necessary to prevent particulate contamination. For example, Krytox low vapor pressure (LVP) high-vacuum grease demonstrates superior performance compared to silicone, hydrocarbon, and chlorofluorocarbon greases under extreme temperature and pressure conditions. It operates reliably at vapor pressures as low as 10⁻¹³ mmHg, across temperature ranges from –15°C to 300°C, and in harsh chemical environments, highlighting its consistent and proven effectiveness in demanding applications.

Key Market Trends & Insights

- Europe dominated the global vacuum grease market with a revenue share of 44.2% in 2023.

- Germany led the European vacuum grease market in 2023.

- By product, the fluorocarbon-based segment dominated the market, accounting for a 69.9% share in 2023.

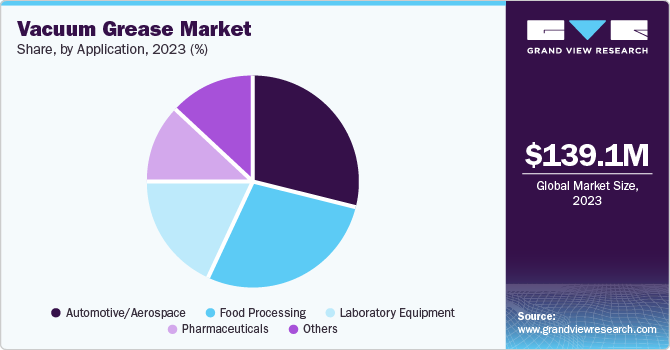

- By application, the automotive/aerospace segment held the largest share at 29.4% in 2023.

Download a free sample PDF of the Vacuum Grease Market Intelligence Study by Grand View Research.

Market Size & Forecast

- 2023 Market Size: USD 139.1 Million

- 2030 Projected Market Size: USD 209.2 Million

- CAGR (2024–2030): 6.0%

- Europe: Largest market in 2023

Competitive Landscape

The vacuum grease market is moderately competitive, with key players focusing on product innovation, strategic collaborations, and application-specific formulations to strengthen their market presence. Companies are increasingly developing greases that offer superior vacuum stability, chemical resistance, and thermal performance to meet evolving industrial requirements.

- Dow manufactures high-vacuum grease solutions for a wide range of industrial applications, including pharmaceuticals. Dow Corning High Vacuum Grease is known for its excellent sealing and lubricating properties and is widely used in valves, gaskets, O-rings, bearings, and vacuum systems. Market expansion is supported by technological advancements and increasing demand from industries such as aerospace, electronics, and pharmaceuticals.

- CASTROL LIMITED, a UK-based lubricant manufacturer, offers the Braycote 803 Series of high-vacuum greases, designed for applications where conventional greases fail. These products are critical for maintaining vacuum integrity and preventing contamination in sensitive processes, including pharmaceutical manufacturing and packaging.

Key Vacuum Grease Companies

The following companies collectively hold a significant share of the global vacuum grease market and influence industry trends:

- Dow

- M&I Materials Ltd.

- CASTROL LIMITED

- Maax Lubrication Pvt Ltd

- Shin-Etsu Chemical Co., Ltd.

- MPT Industries

- The Chemours Company

- Solvay

- Supervac Industries LLP

- Eastern Petroleum

- Kluber Lubrication

Explore Horizon Databook – the world’s most comprehensive market intelligence platform by Grand View Research.

Conclusion

The vacuum grease market is expected to witness steady growth through 2030, supported by increasing demand for contamination-free manufacturing environments, advancements in precision engineering, and expanding applications across pharmaceuticals, aerospace, electronics, and food processing industries. As industries continue to adopt stricter cleanliness and performance standards, high-quality vacuum grease will remain a critical component in ensuring operational reliability and process efficiency.

No comments:

Post a Comment