Heat Treating Industry Overview

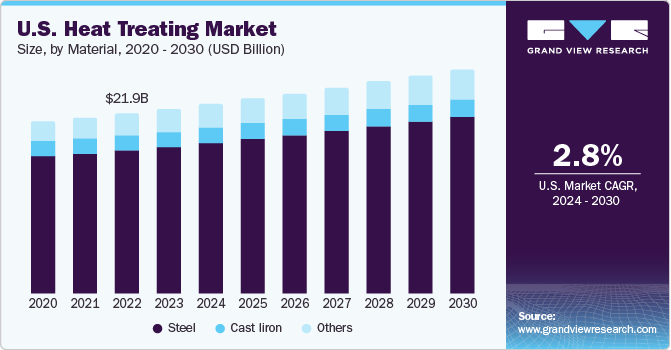

The global heat treating market size was valued at USD 100.73 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 3.4% from 2022 to 2030.

The rapid growth of the electric vehicle industry, coupled with the growing demand for metallurgical alterations to suit specific applications, is expected to boost the market growth over the forecast period. The pandemic is likely to accelerate the adoption of electric vehicles and is likely to become a key factor for major structural changes in this process, which is highly used in the automotive industry. EVs require heat treatment for specialized materials in DC and AC motors, laminations, bearings, and shafts. Heat treatment for EVs requires a flexible heat treating approach and is likely to increase the demand for new equipment over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Global Heat Treating market

The COVID-19 pandemic resulted in significant losses for the automotive industry of the U.S. resulting in supply chain and raw material price volatility. Moreover, the pandemic accelerated the growing environmental concerns, which are anticipated to increase the demand for environmentally-friendly heat treatment equipment over the forecast period.

Heat treatment processes that are commonly used to improve the microstructure of these automotive components encompass annealing, isothermal annealing, normalizing, spheroidizing, quenching, tempering, austempering, and case hardening. Growing requirements for lightweight and fuel-efficient automobiles motivated the demand for heat treating to achieve desirable properties of automotive components.

The pandemic is expected to trigger self-sufficiency in manufacturing, primarily in the U.S. and Europe. Increased use of technologies such as IIOT technology and application of data analytics and continuous monitoring of furnaces are expected to augment the industry growth over the forecast period.

The furnaces used in heat treating consume a significant amount of energy to achieve the desired temperature required for heating the metals. The conventional gas-fired and fuel-fired furnaces use fossil oil (FO) and light diesel oil (LDO) as fuel for heat treating. This leads to higher heat losses and thus high environmental impact, which is likely to hamper the industry growth.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

India Heat Treating Market - The India heat treating market size was valued at USD 3.8 billion in 2016 and is estimated to register a remarkable CAGR of 7.5% from 2017 to 2027. Heat treating is an industrial process used to modify and improve various mechanical properties of materials, such as wear strength, fatigue resistance, and surface hardness.

Heat Treated Steel Plates Market - The global heat treated steel plates market size was valued at more than USD 5.8 billion in 2019 and is anticipated to expand at a CAGR of 3.9% from 2020 to 2027.

Key Companies profiled:

Some prominent players in the global Heat Treating market include

- Bluewater Thermal Solutions LLC

- American Metal Treating Inc.

- East-Lind Heat Treat Inc.

- General Metal Heat Treating, Inc.

- Shanghai Heat Treatment Co. Ltd.

- Pacific Metallurgical, Inc.

- Nabertherm GmbH

- Unitherm Engineers Limited

- SECO/WARWICK Allied Pvt. Ltd.

- Triad Engineers

Order a free sample PDF of the Heat Treating Market Intelligence Study, published by Grand View Research.

No comments:

Post a Comment